In the world of stainless steel fittings, precision and quality assurance are paramount. Whether you're a manufacturer, distributor, or a discerning consumer, ensuring that the stainless steel fittings you use meet the highest standards is crucial. This is where Material Test Reports (MTRs) come into play as an indispensable tool.

Imagine you're constructing a state-of-the-art industrial facility, designing a cutting-edge aerospace component, or even just looking to upgrade the plumbing in your home. The foundation of all these endeavors rests upon the quality of the stainless steel fittings you choose. To ensure the reliability and durability of these fittings, you need a document that serves as their birth certificate, and that's precisely what Material Test Reports provide.

We'll delve deep into stainless steel and uncover the significance of Material Test Reports (Mill test certificate). So, let's embark on this journey to unravel the mysteries and explore the role of ensuring the integrity and performance of metal fittings.

Interpreting Material Test Report (MTR)

interpreting an MTR is essential for ensuring that materials used in various industries meet the specified requirements and standards. Here's a breakdown of the steps involved in interpreting an MTR:

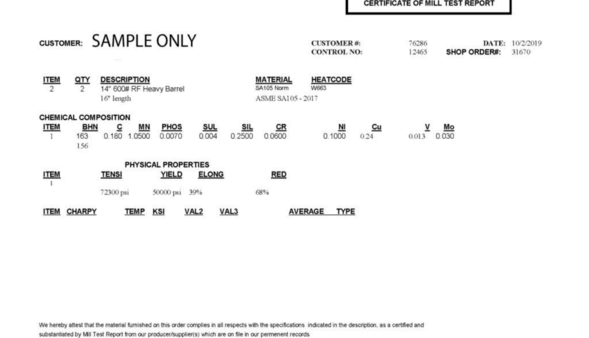

Step 1: Customer Details

This section provides information about the customer who ordered the material, including their name, address, contact information, and possibly a purchase order number. It helps in tracking the material to the correct customer and order.

Step 2: Product Specification

This section describes the product for which the material is intended. It includes details like the product name, part number, drawing or specification references, and any other relevant product information. It also lists the same specification of the material or standard that the product must meet.

Step 3: Heat Codes

The heat code, also known as the heat number or heat batch number, is a unique identifier assigned to a batch of material during its production. It allows traceability back to the specific manufacturing process, including the furnace, date, and other production details. This information is crucial for quality control and identifying potential issues.

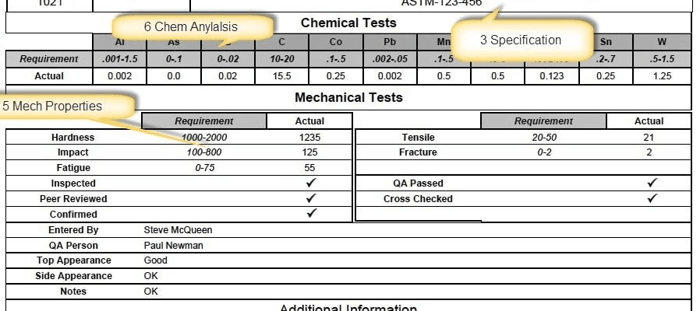

Step 4: Chemical Analysis

This section provides details about the chemical properties of the material. It typically includes a table with percentages or values of various elements present in the material, such as carbon, silicon, manganese, sulfur, phosphorus, and others. The chemical composition should meet the specified requirements and standards.

Sep 5: Physical Properties

In this section, you'll find information about the physical properties of the material, which can include:

Mechanical properties: These include values like tensile strength, yield strength, elongation, and hardness. These properties indicate how the material will behave under mechanical loads.

Dimensional properties: This includes measurements such as thickness, width, length, and other dimensional characteristics.

Microstructure: Information about the material's microstructure, which can be important for certain applications.

Ensure that the material's physical properties meet the required specifications and standards.

Step 6: Heat Treatment

If the material has undergone any heat treatment processes, this section will provide details. Heat treatment processes can include annealing, quenching, tempering, or other treatments to alter the material's properties. The MTR will specify the type of heat treatment, temperature, duration, and any other relevant parameters.

Step 7: Quality Assurance

This section summarizes the quality assurance processes that were applied during the material's production and testing. It may include information about inspections, tests, and certifications conducted to ensure that the material meets the specified standards and requirements. Look for any non-conformance reports or additional quality assurance documentation.

What are the Benefits of MTR Certs?

We now know that this document is critical in various industries, particularly in manufacturing and construction. Its importance lies in the following key aspects:

Quality Assurance

MTRs provide detailed information about the material used in a product or project, including its composition, mechanical properties, and any applicable industry standards or specifications. This ensures that the material meets the required quality standards and is suitable for its intended use.

Traceability

MTRs contain information about the source of the material, including the manufacturer, heat number, and batch number. This traceability is essential for tracking the material's origin and ensuring it meets the necessary specifications.

In cases of defects or failures, traceability helps identify the responsible party and facilitates recalls or corrective actions.

Compliance

Many industries have stringent regulations and standards that materials must meet to ensure safety, performance, and compliance with environmental regulations. MTRs provide evidence that materials used in a project or product meet these regulatory requirements, reducing the risk of non-compliance issues.

Liability and Documentation

MTRs serve as legal documents that can be used in case of disputes or claims related to the quality or performance of materials. Having accurate and comprehensive MTRs can protect manufacturers, suppliers, and contractors from potential legal liabilities.

Quality Control

MTRs are essential tools for quality control and quality assurance processes. They help manufacturers and inspectors verify that materials are consistent with the specified requirements, preventing the use of substandard materials that could compromise the integrity of a project or product.

Material Selection

Engineers and designers often rely on MTRs when selecting materials for specific applications. The data in the MTR, such as tensile strength, chemical composition, and hardness, help them make informed decisions about which materials are best suited for their needs.

Documentation for Certification and Audits

In industries where certification and third-party audits are required, MTRs are crucial for demonstrating compliance with industry standards and specifications.

They provide the necessary documentation to support certification processes and audits by regulatory bodies.

Safety and Reliability

Using materials with known properties and characteristics, as confirmed in the MTR, is essential for ensuring the safety and reliability of structures, machinery, and products.

It reduces the risk of material-related failures and accidents.

Buy Certified mill test report Fittings from Ace Stainless Steel

Buying certified mill test report (MTR) fittings from a reputable supplier like Ace Stainless Steel can offer several benefits and advantages.

Here are some reasons why you might consider purchasing MTR fittings from Ace Stainless Steel:

Quality Assurance

Certified MTR fittings come with documentation that verifies the quality and composition of the materials used in their construction. This helps ensure that you are getting high-quality fittings that meet industry standards.

Compliance

Many industries and applications require fittings that meet specific standards and regulations - mill test reports. Certified MTR fittings (raw material) are more likely to meet these requirements, ensuring compliance and safety in your operations.

Conclusion

Buying certified material test report fittings from reputable suppliers can provide you with quality assurance, compliance, documentation, and peace of mind. This will ultimately contribute to the reliability and performance of your systems and operations.