When it comes to heating and plumbing systems, the integrity of pipework connections is paramount. Properly connecting pipes and fittings is the backbone of a well-functioning system. Whether you are a seasoned professional or a DIY enthusiast, understanding the art of pipework connections is essential.

Before we dive into the specifics of pipework connections, let's grasp the fundamentals. In any heating or plumbing system, pipes and fittings serve as the circulatory system. They transport water, gas, or other fluids efficiently and safely. The quality of connections directly impacts system performance, safety, and longevity.

In this comprehensive guide, we will explore the ins and outs of connecting pipes and fittings for heating and plumbing systems. We shall also inform you where you can get quality connecting pipes and other fittings in the US.

Let us get started;

Types of Pipes and Fittings

When it comes to plumbing systems, choosing the right type of pipes and fittings is essential for ensuring durability, efficiency, and the smooth flow of water or other fluids. So, we will dive into the world of pipes and fittings, exploring various materials and their applications.

Whether you're planning a new plumbing project or just looking to replace some old pipes, understanding the options available can make all the difference.

What are the Different Types of Pipes?

In plumbing projects, you will come across these types of pipes:

Stainless Steel Pipes

Steel pipes are robust and long-lasting, making them an ideal choice for high-pressure systems and gas lines. They are known for their strength and durability, making them suitable for industrial applications as well. While steel pipes are heavy and can be challenging to work with, their ability to withstand extreme pressure and temperature conditions makes them indispensable in specific scenarios.

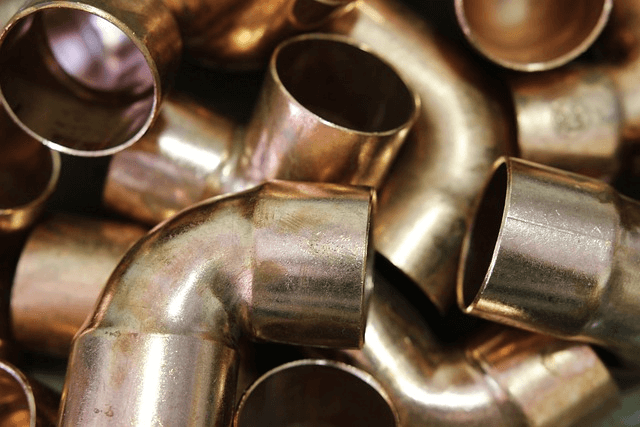

Copper Pipes

Copper pipes have been a staple in plumbing for decades, and for good reason. They are known for their durability, corrosion resistance, and longevity. Copper pipes are commonly used in water supply systems, both for residential and commercial purposes. Their resistance to rust and corrosion means they maintain water quality and pose fewer health risks compared to some other materials.

PEX Pipes

PEX pipes, short for cross-linked polyethylene pipes, have gained popularity due to their flexibility and ease of installation. These pipes are perfect for tight spaces where rigid pipes might be challenging to fit. PEX pipes are resistant to freezing, which makes them a great option for cold climates. They are commonly used for both hot and cold water supply systems and are known for their affordability.

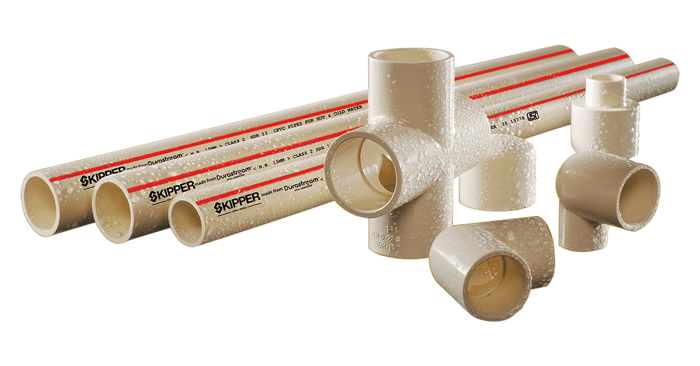

CPVC Pipes

Chlorinated polyvinyl chloride (CPVC) pipes are designed to withstand both hot and cold water applications. They are durable and offer excellent chemical resistance, making them suitable for various plumbing needs. CPVC pipes are often used for water distribution in residential buildings, as they are easy to install and less likely to corrode than metal pipes.

PVC Pipes

Polyvinyl chloride (PVC) pipes are lightweight and corrosion-resistant, making them a go-to choice for drainage systems and low-pressure applications. PVC pipes are easy to install, cost-effective, and suitable for both residential and commercial projects. They come in various sizes and are known for their longevity when used in the right context.

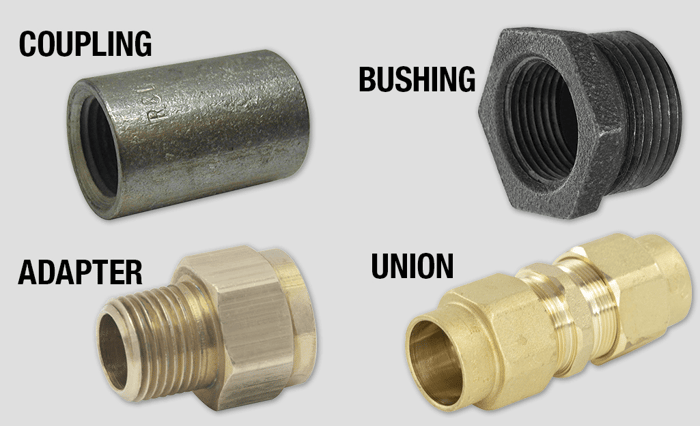

What are the Types of Fittings?

Apart from selecting the appropriate pipes, choosing the right fittings is equally important for a successful plumbing project. Here are some common types of fittings:

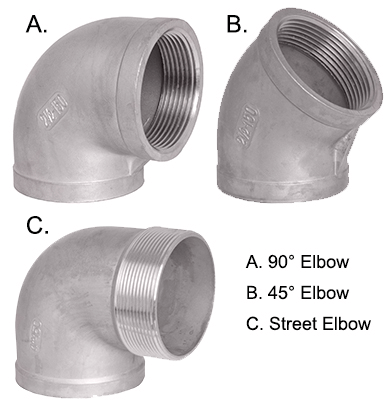

Elbow Fittings

Elbows are used to change the direction of the pipe, typically at 90 or 45-degree angles. They are crucial for navigating around obstacles in plumbing systems.

Coupling Fittings

Couplings are used to join two pipes together. They come in various materials, such as copper, brass, and PVC, to suit the type of pipes being connected.

Tee Fittings

Tee fittings create a T-shaped junction in the plumbing system, allowing for a third pipe to branch off from the main line. They are essential for creating complex plumbing configurations.

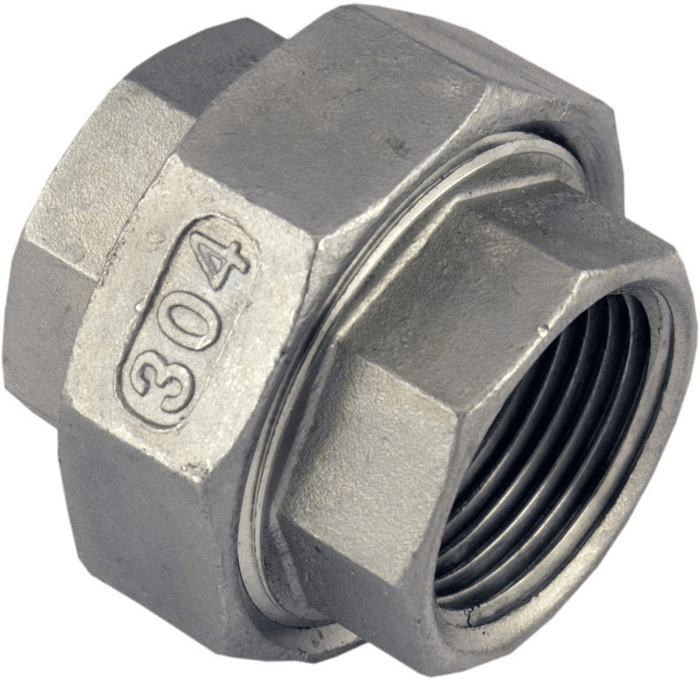

Union Fittings

Union fittings provide a detachable joint in the plumbing system, allowing for easy maintenance and repairs without needing to cut the pipe.

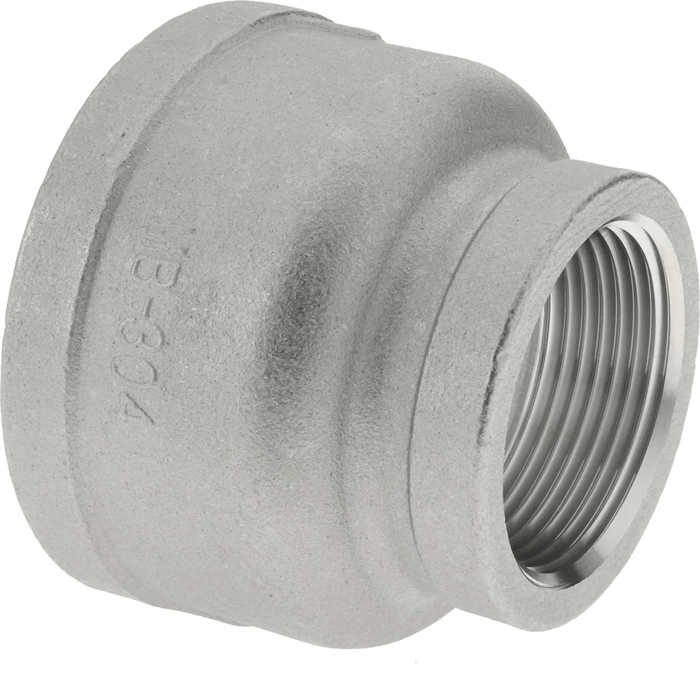

Reducer Fittings

Reducers are used to connect pipes of different sizes, ensuring a smooth transition and maintaining proper flow rates.

Why Pipe Fittings?

These are mechanical components used to connect and join different sections of pipes or tubing. These fittings serve a vital purpose in ensuring the integrity of a piping system. They come in various shapes, sizes, and materials to suit the specific needs of different industries and applications.

The primary functions of pipe fittings include:

Connection

Fittings are used to join two or more pipes together, allowing for the creation of a continuous pipeline.

Directional Changes

They redirect the flow of fluids when necessary, facilitating efficient fluid movement through a system.

Termination

Pipe fittings can be used to end a pipeline or connect it to a piece of equipment or another system component.

Regulation

Some fittings, such as valves, enable control over the flow rate and pressure within a system.

Types of Pipe Fittings Connection

Pipe fittings are essential components in any plumbing or piping system, serving as the connective tissue that holds pipes together and ensures the smooth flow of liquids or gases. However, as a professional plumber or enthusiast, understanding different connections is essential.

Here is what you need to know:

Threaded Pipe Fittings

Threaded pipe fittings are among the most commonly used connections in plumbing and industrial applications. These fittings have threads on both the inside and outside, allowing pipes to be screwed together (female threads and male threaded pipe. The most popular thread standards are NPT (National Pipe Thread) and BSP (British Standard Pipe threads).

Applications: Threaded fittings are ideal for low-pressure systems, such as water distribution, air compression, and natural gas lines.

Advantages: They are easy to install, disassemble, and replace, making them versatile for various applications.

Socket Weld Pipe Fittings

Socket weld fittings are used for high-pressure applications, where a strong connection is required. These fittings have a female socket that fits over the pipe end, which is then welded for a secure bond.

Applications: Socket weld fittings are commonly found in industries handling high-temperature and high-pressure fluids, such as petrochemical and chemical plants.

Advantages: They provide a robust and leak-proof connection suitable for demanding conditions.

Butt Weld Pipe Fittings

Butt weld fittings are known for their exceptional strength and durability. They involve welding the pipe ends together directly, resulting in a seamless connection.

Applications: Butt weld fittings are used in critical applications like nuclear and power plants, where structural integrity is paramount.

Advantages: They offer superior strength and are resistant to leakage, making them suitable for high-stress environments.

Compression Fittings

Compression fittings are versatile and easy to install. They consist of a compression nut and a ferrule, which compresses around the pipe when tightened, creating a secure seal.

Applications: Compression fittings are commonly used in domestic plumbing for connecting copper or plastic pipes.

Advantages: They are user-friendly and allow for disassembly without damaging the pipe.

Flanged Pipe Fittings

Flanged fittings involve bolting together two flanges with a gasket in between, creating a strong, leak-resistant connection. These fittings are common in large-diameter pipes.

Applications: You'll find flanged fittings in industries handling corrosive or abrasive fluids, like sewage treatment plants.

Advantages: They are suitable for high-pressure applications and can be easily aligned during installation.

Grooved Pipe Fittings

Grooved fittings are designed with grooves on both the pipe and fitting ends. These grooves are connected using a gasket and coupling, creating a flexible, yet reliable, connection.

Applications: Grooved fittings are popular in fire protection systems and HVAC and industrial piping.

Advantages: They are quick to install, accommodate movement, and are ideal for large-diameter pipes.

How to Connect Pipes & Fittings

Connecting pipes and fittings is a crucial skill in various industries, from plumbing and construction to DIY projects. Here are the critical aspects to help you master the art of connecting pipes and fittings.

Pipe Material and Sizes

Choosing the right pipe material and size is the first step in creating a successful pipe connection. Different applications require different materials, and it's crucial to select the appropriate one to ensure the longevity and effectiveness of your plumbing or piping system.

Pipe Sizes

Pipe sizes are typically measured in nominal sizes, which may not always correspond to the actual dimensions. Common sizes for residential plumbing include 1/2 inch, 3/4 inch, 1 inch, 1.5 inch, and 2 inches.

It's crucial to match the pipe size with the intended use and follow local building codes and regulations when selecting the right size.

How to Cut Pipes

Properly cutting pipes is essential to ensure that they fit together securely and create a leak-free connection. Here are the steps to cut pipes accurately:

Gather your tools

Pipe Cutter: A pipe cutter is a specialized tool designed to cut copper pipe, plastic pipe, or other piping systems cleanly and evenly. There are different types of pipe cutters available, including ratcheting, rotary, and reciprocating.

Measuring Tape: Measure the length you need and mark it on the pipe.

Safety Gear: Wear safety goggles and gloves to protect yourself from any debris or sharp edges.

Mark the cut

Use a pencil or marker to mark the point on the pipe where you intend to make the cut. Ensure that the mark is straight and even.

Cut the pipe

If you're using a ratcheting pipe cutter, place it on the marked spot and apply pressure. Rotate the cutter around the pipe in a circular motion until the pipe is cut through.

For a rotary pipe cutter, place the cutting wheel on the mark and slowly turn the tool around the pipe, tightening it gradually (you can use a pipe wrench) until the pipe is cut.

If using a reciprocating saw with a metal-cutting blade, ensure the pipe is securely clamped, and then make a straight, even cut along the marked line.

Remove burrs

After cutting, use a deburring tool or a file to remove any sharp edges or burrs from the cut end of the pipe. This step is essential to prevent damage to O-rings and ensure a proper fit with fittings.

How to Bend Pipes

Bending pipes is a crucial skill in plumbing, especially when dealing with tight spaces or complex layouts. There are several methods to bend pipes, each suited for different situations. Here's how you can bend pipes effectively:

Manual Pipe Bending

Manual pipe bending is the most straightforward method and is suitable for softer materials like copper and aluminum. Here's how to do it:

Measure and Mark: Start by measuring the length you need and mark it on the pipe using a pencil or a marker.

Use a Pipe Bender: Place the pipe into a pipe bender, aligning the mark with the desired bend point. Apply steady, even pressure on the bender's handle to create the bend. Be sure to follow the manufacturer's instructions for the specific bender you're using.

Check the Angle: Use a protractor or angle finder to ensure the bend is at the correct angle. Adjust as needed.

Using a Pipe Spring Bender

Pipe spring benders are useful when making small, precise bends. Here's how to use one:

Prepare the Pipe: Insert the spring bender into the pipe and make sure it's positioned where you want the bend to occur.

Bend Gradually: Apply gradual and even pressure to the pipe while bending it in the desired direction. Keep a close eye on the angle as you bend.

Hydraulic Pipe Bending

Hydraulic pipe benders are ideal for heavy-duty applications. They're commonly used for steel pipes. Here's how to use one:

Set Up the Machine: Position the pipe in the hydraulic pipe bender and secure it in place.

Hydraulic Pressure: Operate the hydraulic pump to apply gradual pressure to the pipe, causing it to bend. Follow the equipment's instructions carefully.

How to Connect Pipes

Connecting pipes and fittings is where plumbing truly comes together. Whether you're repairing a leak or installing a new system, the following steps will guide you through the process:

Gather Your Materials

Before you begin, ensure you have all the necessary materials and tools. This includes pipes, fittings, pipe wrenches, Teflon tape, and pipe joint compound.

Measure and Cut

Measure the pipes you need and cut them to the appropriate length using a pipe cutter. Ensure the cuts are clean and square.

Prepare the Ends

Clean the cut ends of the pipes with a deburring tool to remove any burrs or rough edges. This ensures a proper seal when connecting fittings.

Apply Teflon Tape

Wrap Teflon tape around the threads of the pipe fittings in a clockwise direction. This helps create a watertight seal when connecting the pipes.

Use Pipe Joint Compound

For added security, you can apply pipe joint compound to the threads in addition to Teflon tape.

Connect the Pipes

Thread the pipes into the fittings, ensuring a tight connection. Use pipe wrenches to secure the pipes in place, but be careful not to overtighten, as this can damage the fittings.

Test for Leaks

Turn on the water supply and inspect the connections for any leaks. If you spot a leak, tighten the connection slightly until it stops.

Insulate (if necessary)

If you're working with hot water pipes, consider insulating them to conserve energy and prevent heat loss.

Connecting pipes and fittings may seem daunting, but with the right tools and knowledge, it becomes a manageable task. Remember that safety always comes first, so ensure you're using the correct materials and following local plumbing codes.

FAQs: Pipework Connections

Do you still want to know more about plumbing and construction pipework? Check our frequently asked questions:

What are the connections of piping?

Piping connections are essential components within various industries, serving as the lifelines of fluid transport and distribution systems. These connections play a pivotal role in ensuring the seamless flow of liquids or gases, and they come in a diverse range of types and configurations. Each connection method serves a specific purpose, from the ubiquitous threaded connections that enable easy assembly and disassembly to the more complex welded joints that offer unparalleled strength and durability. Flanges, couplings, and fittings are just a few examples of these vital connections, each designed with distinct features to accommodate the unique demands of different applications. Understanding the connections of piping is crucial for engineers, plumbers, and anyone involved in fluid transportation systems to ensure safety, efficiency, and reliability in their operations. Whether it's a household plumbing system or an intricate industrial network, the right choice of piping connections is paramount to keeping things flowing smoothly.

What are the three types of plumbing connections?

When it comes to plumbing, understanding the three primary types of plumbing connections is essential for homeowners and professionals alike. These connections play a pivotal role in ensuring a leak-free and efficient plumbing system. The first type is soldered or sweat connections, which involve heating and melting a solder material to create a watertight seal between pipes and fittings. The second type is threaded connections, where pipes have threads that screw into matching fittings, creating a tight and secure joint. Lastly, there are push-fit or compression connections, which require no special tools and simply involve pushing pipes or fittings together to form a reliable connection. Each of these plumbing connections has its advantages and best-use scenarios, making it vital to choose the right one for your specific plumbing needs.

What is pipework in plumbing?

Pipework in plumbing refers to the intricate network of pipes and tubing that forms the circulatory system of a plumbing system. It serves as the essential infrastructure for the conveyance of water, gas, or other fluids within a building, ensuring that clean water reaches various fixtures while wastewater is safely carried away. Properly installed and maintained pipework is crucial for maintaining the overall functionality and efficiency of a plumbing system. From copper to PVC, pipework comes in various materials, each with its unique advantages, making it vital for plumbers to select the right materials for specific applications. In summary, pipework is the unsung hero of plumbing, silently facilitating the flow of fluids and ensuring the comfort and hygiene of our daily lives.

What is the connection between two pipes?

The connection between two pipes plays a crucial role in plumbing and fluid transport systems. It serves as the bridge that ensures a seamless flow of liquids or gases from one pipe to another. Proper pipe connections are vital for preventing leaks, maintaining structural integrity, and optimizing the efficiency of the entire system. Different types of connections are used depending on the application, including threaded connections, welded joints, flanges, and couplings. Each connection method offers distinct advantages and is selected based on factors such as the type of fluid being transported, pressure requirements, and environmental conditions. Ultimately, a well-executed pipe connection is the cornerstone of a reliable and efficient piping system, making it an essential consideration for any plumbing or industrial project.

Conclusion

Whether you're bending pipes to fit a unique layout or connecting pipes to create a plumbing system, these skills are essential for any DIY enthusiast or professional plumber. By mastering these techniques, you can tackle a wide range of plumbing projects with confidence, ensuring your plumbing systems are both functional and leak-free. Happy plumbing!

Buy Pipe Fittings from Ace Stainless

When it comes to sourcing pipe fittings, you want nothing but the best. Whether you're a professional in the plumbing industry or a DIY enthusiast, the quality and reliability of your pipe fittings can make or break your project. That's where Ace Stainless comes into the picture. These are reasons why buying pipe fittings from Ace Stainless is a smart choice.

Unmatched Quality

One of the foremost reasons to consider Ace Stainless for your pipe fitting needs is their commitment to delivering unmatched quality. We take pride in our reputation for producing high-grade stainless steel fittings that meet and exceed industry standards. The use of premium materials ensures durability, corrosion resistance, and longevity, making Ace Stainless fittings a cost-effective choice in the long run.

Wide Range of Options

Ace Stainless recognizes that every project is unique and demands different types of pipe fittings. We offer a diverse range of options to cater to various industries and applications. Whether you need elbows, tees, reducers, or any other type of fitting, you can trust Ace Stainless to have the right product for your needs. Their extensive inventory allows you to find the perfect fit, quite literally.

Precision Engineering

Precision matters when it comes to pipe fittings. Ill-fitting or poorly engineered fittings can lead to leaks, structural issues, and increased maintenance costs. Ace Stainless understands the importance of precision engineering and utilizes cutting-edge technology to manufacture fittings that fit perfectly and perform flawlessly. Our dedication to craftsmanship ensures that your projects are built to last.

Industry Expertise

With decades of experience in the industry, Ace Stainless has developed an unparalleled level of expertise. Our team consists of knowledgeable professionals who are well-versed in the intricacies of pipe fittings. Whether you have questions about materials, specifications, or applications, you can rely on Ace Stainless for expert guidance and advice.

Competitive Pricing

While Ace Stainless is synonymous with quality, our commitment to affordability is equally impressive to steel pipe. We offer competitive pricing without compromising on the excellence of our products. This balance between quality and cost-effectiveness makes Ace Stainless an attractive choice for both large-scale projects and smaller DIY endeavors.

Sustainability

In today's world, sustainability is a key concern. Ace Stainless takes environmental responsibility seriously by using materials and manufacturing processes that minimize carbon footprint. By choosing us for your pipe fittings, you're not only investing in top-notch products but also supporting eco-friendly practices.