In the world of plumbing and industrial applications, precision matters. When it comes to connecting pipes and ensuring a leak-free, efficient flow of liquids or gases, understanding pipe dimensions and fittings is crucial.

Whether you're a seasoned professional or a DIY enthusiast, navigating the complex landscape of pipe fittings can be a daunting task. That's where a pipe fitting size chart comes to the rescue.

Why Pipe Fitting Chart

Imagine this scenario: you've invested time and resources into a plumbing project, only to discover that the fittings you've purchased don't quite match the pipes you're working with. It's a frustrating setback that can lead to costly delays and repairs.

But fear not! With the right knowledge and guidance, you can avoid these pitfalls and make informed decisions about the pipe fittings you need at Ace Stainless Steel.

So, in this blog, we'll delve into the world of pipe fitting size charts, unraveling the mysteries of pipe dimensions and fittings. Whether you're a professional looking to refresh your knowledge or a beginner taking your first steps in the world of pipes, we've got you covered.

If you're ready to master the art of pipe fittings and ensure that your next plumbing or industrial project goes off without a hitch, read on. By the time you finish this blog, you'll be equipped with the knowledge and confidence to buy the right fittings using pipe dimensions, saving you time, money, and headaches along the way.

What is the nominal pipe size?

The nominal pipe size (NPS) is a standardized North American designation used to describe the size of pipes. It does not represent the actual physical dimensions of the pipe but rather serves as a convenient label for identifying and categorizing pipes based on their approximate inside diameter. NPS is typically expressed as a whole number (e.g., 1 inch, 2 inches, 3 inches) and is used primarily in the United States and Canada.

It's important to note that the NPS does not necessarily equal the actual outside diameter or inside diameter of the pipe. The NPS designation is a nominal or approximate size that helps users select compatible fittings and components for plumbing or industrial applications. The actual dimensions of a pipe, including its outside diameter, wall thickness, and inside diameter, can vary depending on the pipe's material and standards (e.g., ASTM, ANSI, ASME).

For instance, a 1-inch nominal diameter pipe does not have a 1-inch outside diameter; instead, it typically has an outside diameter slightly larger than 1.3 inches. The exact dimensions can be determined by referring to pipe size charts and specifications provided by relevant standards organizations or manufacturers.

In other words, the nominal size (NPS) is a standardized label used to describe the size of pipes in North America, but it is not a direct representation of the pipe's actual physical dimensions. Users should consult pipe size charts and standards to obtain precise information about a specific pipe's dimensions and nominal bore.

Using ID vs. OD Fittings

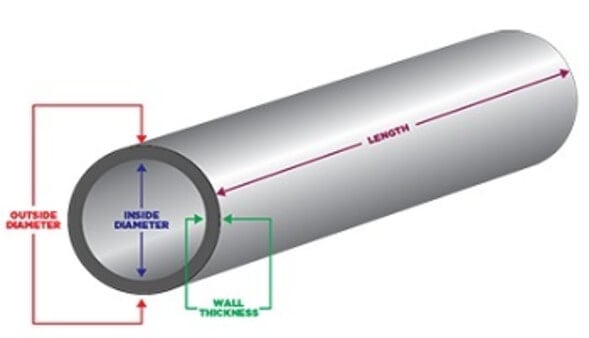

The choice between using ID (inside diameter) and OD (outside diameter) fittings depends on the specific requirements and characteristics of the piping system or application you are working with. Here are some guidelines to help you decide when to use each type of fitting:

Inside Diameter (ID) Fittings

ID fittings are typically used when you need to connect pipes based on the inner diameter of the pipe.

Flow capacity is a critical consideration: ID fittings are often used when you want to maximize the flow rate of liquids or gases through the system. Using fittings that match the inside diameter of the pipe ensures minimal flow restriction.

In situations where you need a snug fit: ID fittings are ideal when you want a tight and secure connection between pipes, especially if you're dealing with thin-walled pipes or tubing.

Outside Diameter (OD) Fittings

OD fittings are generally used when you need to connect pipes based on the outer diameter of the pipe (pipe wall thickness) which is the actual diameter.

When dealing with rigid pipes: OD fittings are commonly used with rigid pipes like PVC, copper, and steel. These pipes are typically specified and measured by their outside diameter.

For applications where space is limited: OD fittings can be advantageous in tight spaces where the clearance for fittings is limited. Using OD fittings can help reduce the overall diameter of the system.

When compatibility with existing components is essential: If you have existing pipes or components that are designed for OD connections, it's important to use OD fittings to maintain compatibility.

It's crucial to follow industry standards and guidelines when selecting fittings for a specific application. In many cases, the choice between ID and OD fittings may be determined by the type of pipes you are using, as different materials and industries have their own conventions.

How to measure pipe fittings

Measuring pipe fittings accurately is essential to ensure you select the correct fittings for your plumbing or industrial project. To measure pipe fittings, you'll need to determine key dimensions such as size, thread type, and sometimes the angle or shape of the fitting. Here's a step-by-step guide on how to measure pipe fittings:

Tools and Materials Needed

Measuring tape or calipers

Thread gauge (for measuring external thread, if necessary thread per inch)

Pipe size chart or reference materials

Steps to Measure Pipe Fittings

Step 1: Determine the Type of Fitting

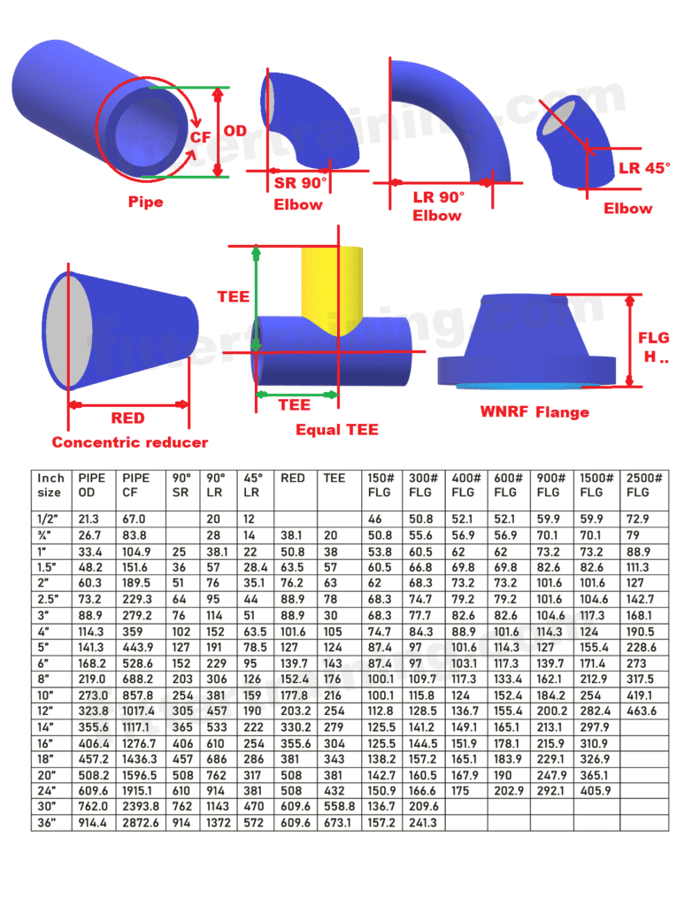

Identify the type of fitting you are measuring. Common types include elbows, tees, couplings, adapters, and more. Each type of fitting serves a specific purpose, so understanding the pipe schedule and fitting's function is crucial.

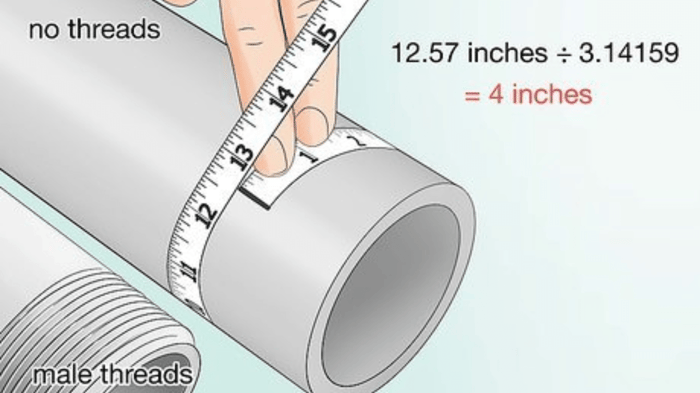

Step 2: Measure the Size (Nominal Pipe Size - NPS)

For most pipe fittings, the key dimension to determine is the nominal pipe size (NPS). This size is expressed in inches and refers to the approximate inside diameter of the pipe the fitting is intended to be used with.

Use a measuring tape or calipers to measure the outside diameter of the pipe if you are uncertain about its NPS. Compare your measurement to a pipe size chart or reference materials to determine the NPS.

Step 3: Identify the Thread Type (If Applicable)

Many fittings, especially those used in threaded connections, have a specific thread type, such as NPT (National Pipe Thread), BSP (British Standard Pipe), or metric threads. It's important to identify the thread type accurately.

Use a thread gauge if necessary to measure the pitch, thread diameter, and thread type of the fitting. Match these measurements with the appropriate thread standard.

Step 4: Determine the Angle or Shape (If Applicable)

For specialized fittings like elbows or tees, you may need to measure the angle of the fitting. This is typically expressed in degrees (e.g., 90-degree elbow).

Measure the angle using a protractor or by comparing the fitting to a reference angle.

Step 5: Consider Material and Pressure Rating

Depending on your application, you may also need to consider the material of the fitting (e.g., brass, stainless steel, PVC) and its pressure rating. Ensure that the fitting is compatible with the materials and pressure levels in your system.

Step 6: Check for Special Features

Some fittings may have unique features or connections, such as compression fittings, flanges, or quick-connect fittings. Take note of any special features or connectors that are relevant to your project.

By accurately measuring metal pipes fittings and understanding their specifications, you can select the right fittings for your plumbing or industrial system. This ensures a proper and secure connection that meets your specific requirements. When in doubt, consult with a professional or refer to industry standards and guidelines for additional guidance.